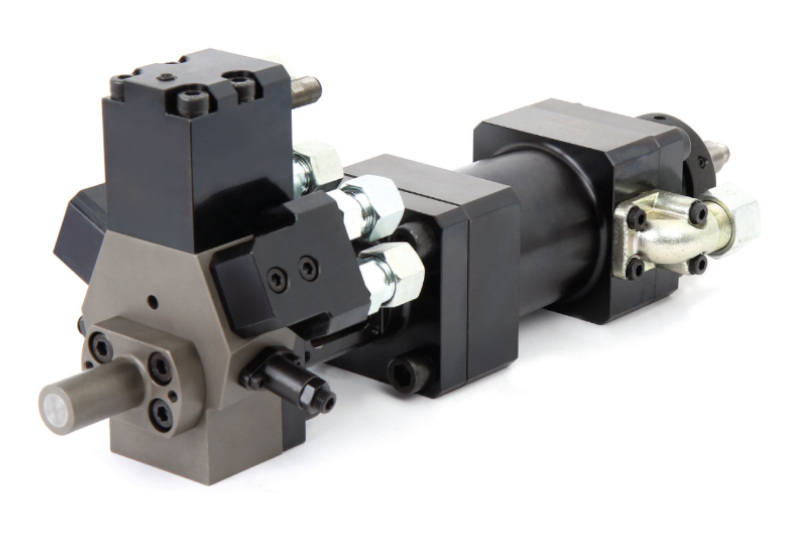

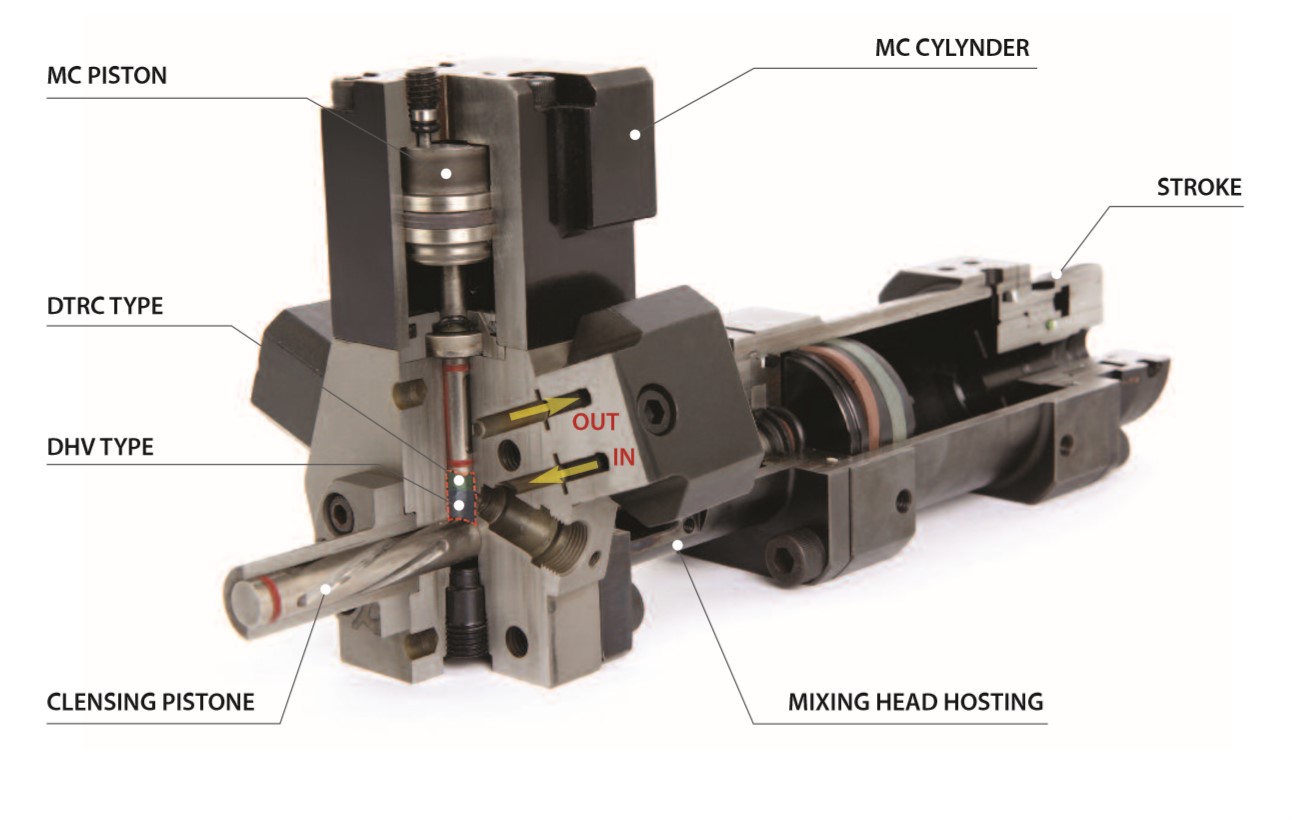

DUT’s Double Tilted Rear Chamber Mixing Head System(DTRC) is designed to make maximum mixing efficiency while still maintaining desirable laminar flow. The DTRC Mix Heads are engineered to provide more chemical stream collisions (Impingement) inside the mix head’s mixing chamber via double tilted nozzle angle. Moreover, the additional space provided in the mixing chamber for mixing is then able to provide the customers with the best mixing efficiency with lower pressure than previous L-type systems that are currently available by other OEM’s.

- DTRC-0608-2k

- DTRC-0608-3k

- DTRC-0710-2k

- DTRC-0812-2k

- DTRC-0812-3k

- DTRC-0812-4k

- DTRC-1014-2k

- DTRC-1218-2k

- DTRC-1218-4k

- DTRC-1625-2k

DTRC Features

• Maximum efficiency by “Double Tilted Rear Chamber Mixing System”

• Ability to obtain the best mixing efficiency with lower pressure than other OEM’s mixing systems

• High compatibility with various type of foaming machine

• Innovative nozzle control for minimum switching times for use with multi-component

• Anti-stick locking design (X-groove technology has applied to cleaning piston) & Anti-scrap floating design.

• Long life cycle & low maintenance costs

• Repeatable Stroke adjustments (for L-Style Mix Heads) from one mix head to the next

• The enhancement of the initial kinetic energy, which is caused by 1st and 2nd collisions

• The kinetic energy and laminar flow are further enhanced by the reversing effect in the extended mixing chamber

• With high viscosity materials, the DTRC maximizes the mixing efficiency by offsetting the process of kinetic energy

• The DTRC provides the softest laminar flow available with the best mixed Polyurethane.

Ready to find out more?

Drop us a line today for a free quote!